Recently, the paper " Waterdrop bouncing off vertically vibrating textured surfaces" by Prof. Zou Jun from the Department of Mechatronic Engineering was successfully published in the Journal of Fluid Mechanics ( JFM). Co-author Stéphane Dorbolo is a researcher funded by the 2018 Open Fund of the State Key Laboratory of Fluid Power and Electromechanical Systems. The open platform of the State Key Laboratory connects two like-minded researchers to conduct international cooperation and interdisciplinary research to achieve mutual benefit and win-win results.

The superhydrophobicity of plant surfaces (such as lotus leaves) in nature makes it self-cleaning and anti-corrosion functions and this property has important application prospects in engineering practice, such as wing anti-icing, clothing self-cleaning and construction. The surface of the object is preserved. Therefore, a large number of researches have been carried out on artificial superhydrophobic materials, and the preparation of superhydrophobic microstructure surfaces has been realized by means of photolithography. The bounce time of droplets on a superhydrophobic surface is the focus of attention, and the possibility of icing or corrosion can be reduced by shortening the contact time. However, studies have shown that the energy dissipation of the droplets as they bounce off the surface of the microstructure results in a significant increase in contact time and a decrease in the rate of detachment, which increases the likelihood of icing or corrosion on the surface of the microstructure. In this paper, the process of droplets exploding from the microstructure surface is studied, and the energy dissipation mode when the liquid-solid interface is detached is revealed, which provides a theoretical basis for optimizing the microstructure design.

The effects of different materials, different shapes and different structural parameters on the critical conditions of droplets ejecting microstructure surface were studied experimentally, where a is the diameter of the circumscribed circle of the microstructure, b is the circumscribed circle of the microstructure, h p is micro Structure height. The materials used in microstructure processing are PDMS and hydrophobic coatings on the surface of the silicon plate.

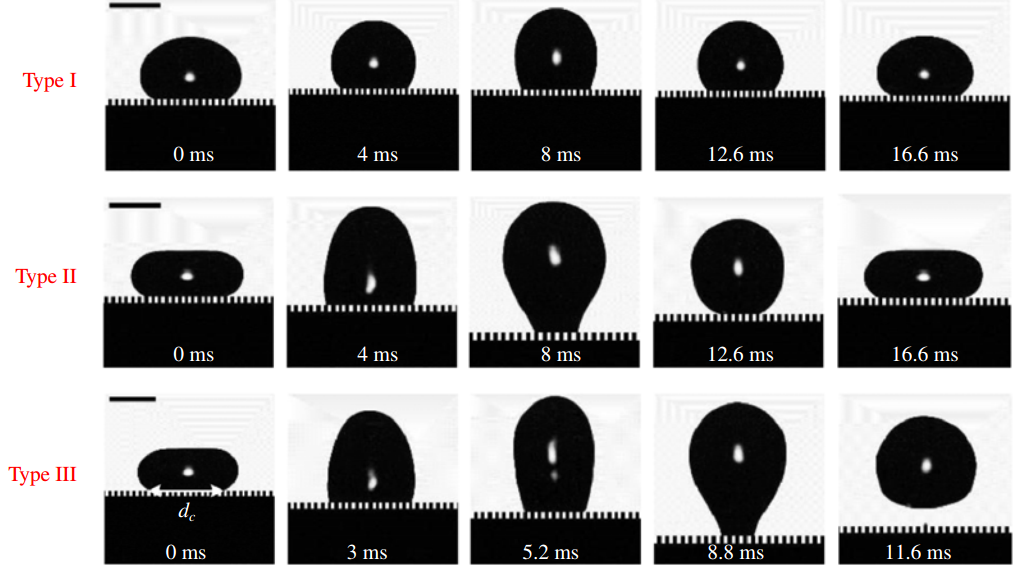

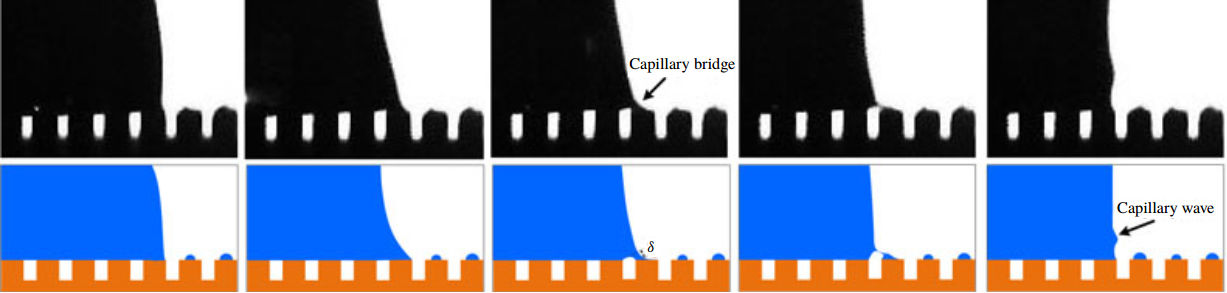

The micro-structure plate is fixed to the vibration table, the vibration frequency is fixed and the amplitude is gradually increased, and the liquid droplets exhibit three motion states: I the liquid-solid contact line remains unchanged, the droplet itself deforms; II the liquid-solid contact line reciprocates and the motion amplitude The value increases as the amplitude of the vibrating table increases; III droplets bounce off the surface of the microstructure.

The experimental results show that the capillary bridge formed when the liquid-solid interface is detached is the main form of energy dissipation. First, the liquid surface shrinks along the surface of the microstructure to form a liquid bridge, which stores the surface tension energy; subsequently, the liquid bridge breaks when it reaches the critical length, and some of the surface energy can be stored in the residual droplets on the surface of the microstructured protrusion and is completely vibrated after repeated vibrations. dissipation can be stored in another portion of the surface capillary wave droplet surface ( capillary wave ), the dissipation occurring in the transfer process. Therefore, the experimental method is used to reveal the energy dissipation mode when the droplets are separated from the surface of the microstructure, which confirms the theoretical conjecture of the predecessors.