Hosted by the National Natural Science Foundation of China, at the 12thICFDM International Academic Conference held in Shenyang, China from August 10 to 12, 2016, 10 national natural science fund outstanding projects were selected by voting. Professor Mei Deqing's fund project of the State Key Laboratory of Fluid Power and Mechatronic Systems, Zhejiang University, “Study on the theory and method of stacking array type thermoelectric power generation components and semi-solid powder micro-forming based on thermoelectric materials” is one of them.

The starting and ending period of the project is from January 2012 to December 2015. The main research contents are: “In today's increasingly serious environmental pollution and energy crisis, the use of thermoelectric materials and their devices to achieve stable,non-polluting waste heat from industrial production and vehicles. Recycling is of great significance. However, the existing low-temperature efficiency and high manufacturing cost of thermoelectric power generation components restrict the wide application of thermoelectric power generation technology. To this end, the project focuses on the design and optimization of thermoelectric component forming and thermoelectric arm dimensions. The research on key technology of functional gradient thermoelectric arm structure design, thermoelectric device integration, and assembly test provides theoretical basis and technical support for the preparation of high-quality thermoelectric materials and the design and manufacture of high-efficiency thermoelectric devices.”

The main research progress and innovations of the project include:

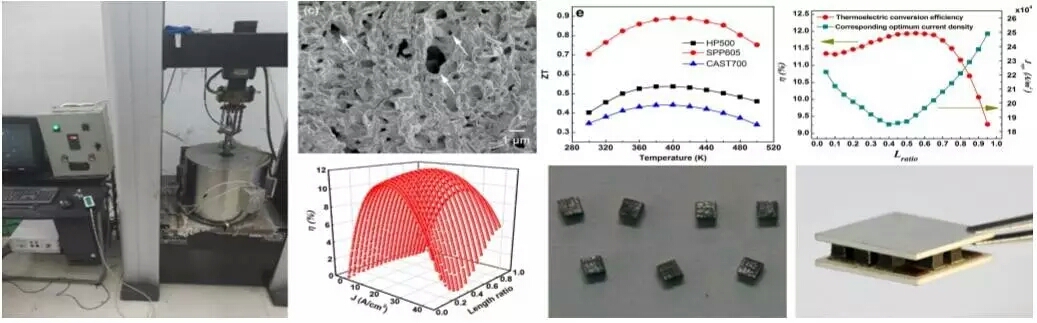

(1)A semi-solid powder forming method capable of obtaining porous materials and an ultrasonic energy field-assisted powder micro-forming method for obtaining nano-crystals were proposed and developed, and low thermal conductivity bismuth telluride and lead telluride thermoelectric blocks were successfully prepared.

(2)The influence of a structural form, size and contact resistance of thermoelectric power generation components on the performance of thermoelectric power generation devices is studied, and the performance evaluation and topology design optimization of thermoelectric power generation components are completed.

(3)The thermoelectric constitutive model of functionally graded thermoelectric components is studied. The design and optimization method of functionally graded thermoelectric components are proposed and developed, and the thermoelectric conversion rate of functionally graded thermoelectric components is effectively improved.

(4)The assembly and test methods of thermoelectric modules were studied and established. Bi2Te3/Sn96.5Ag3Cu0.5/Cu thermoelectric module welding structure foundation, the influence of different welding process parameters on the performance of the thermoelectric module was explored. At the same time, a thermoelectric module performance test platform was established, and the thermoelectric performance test and evaluation of the thermoelectric module were completed.

Fig.1 Manufacturing of porous thermoelectric materials, topology optimization of thermoelectric components and assembly test of thermoelectric modules

The main research results of the project are:

(1)10 SCI Papers, 1 EI paper, were published in international journals such as International Journal of Plasticity, Journal of MaterialsResearch, Journal of Sound and Vibration.

(2)The research results of the project won 16 national inventions patents and 6 utility model patents.

(3)three graduate students, four graduate students