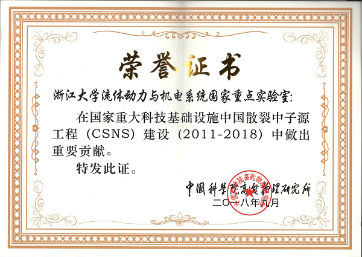

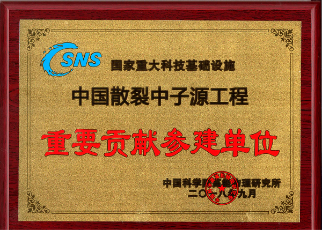

August 23, 2018, the National Major Science and TechnologyInfrastructure China Spallation Neutron Source (CSNS) project passed the national acceptance and was put into formal operation. As one of the important participating units of the project, the State KeyLaboratory of Fluid Power and Mechatronic Systems of ZhejiangUniversity was invited to participate in the completion of the Chinese spallation neutron source project held in the Dongguan Branch of the Institute of High Energy Physics of the Chinese Academy of sciences on September 26, and honored with the plaque and honorary certificate of the “Important Contributions Participating Unit”issued by the Institute of High Energy Physics of the Chinese Academy of Sciences.

Chinese spallation neutron source is a major scientific device constructed during the “Twelfth Five-Year Plan” period inChina. It is included in the national medium- and long-term scientific and technological development plan, and is a large-scale research platform for high-tech multidisciplinary applications at the forefront of the international market. As the first spar neutron source in developing countries, it will enter the ranks of the world's four sparse neutron sources, which will help to improve the level of basic research and high technology in China.

Since the project started construction in 2011, the team of the State KeyLaboratory Professor Xu Bing has participated in the special equipment such as the spar neutron source switch neutron beam gate hydraulic lifting system, high-precision four-knife diaphragm,automatic sample changing device and so on, Among which the neutron beam switch is one of the key equipment for the Chinese spallation neutron source. The normal operation of the equipment is directly related to the effective utilization of the neutron beam and the radiation safety of the personnel in the laboratory hall, and a device is a machine, The integrated system of electric and liquid integration, vacuum and collimation, and other multi-professional intersections is difficult to develop. After many years of research by the team, it has broken through a number of key technologies and has completed the research and development of prototypes (2012), the first prototype of the project (2015) and the mass production of engineering products (2016), the total number of neutron beam switches. The Cheng-Shui hydraulic motion control system has completed on-site acceptance. After the expert group appraisal, motion control stability, durability test, and electrical control safety and other indicators have reached the international advanced level.